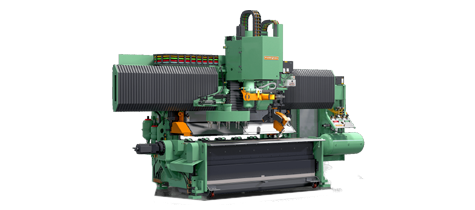

HSFDB-C

Overview

Structural Steel Plate Processor - High Speed Carbide Drilling - Plasma Cutting - Oxy-Fuel Cutting - Bevel Cutting - Milling - 12-Station Tool Changer - Siemens Spindle Motors - SignoMat Part Stamping - Roller Feed Measurement - Minimum Quantity Lubrication - Superior Clamping System - Peddinghaus Control - Front End Unloading System - Side Unloading System

Handle Volumes of Heavy Plate Production

The HSFDB-C is the high speed solution for heavy plate production. This machine encompasses multiple capabilities, provides greater flexibility and maintains complete control of the quality in finished projects. Process an average of 1 ton per hour on materials up to 1" (25 mm) in thickness and 2 tons per hour on materials above 1" (25 mm) in thickness.

High Speed Heavy Beveling

The HSFDB-C boasts features such as bevel cutting, SignoMat stamping and an expansive 12-station tool changer. Structural fabricators, manufacturers and service centers the world over have learned quickly that this concept is the answer to the problems that older plasma cutting technologies present.

Process

4" Thick Plate

Tool Changer

12 Station